PERFECTION MEANS PROVIDING THE PERFECT TECHNICAL MOLDED PART FOR ANY REQUIREMENT.

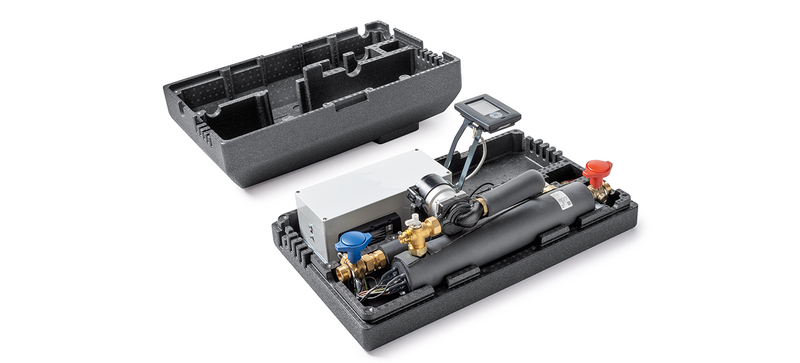

Storopack has developed and manufactured technical molded parts tailored to customers’ needs and applications for decades. The chief benefits of expanded plastics are that they are extremely lightweight and can be flexibly shaped. At the same time, technical molded parts can be used in different densities. They offer outstanding insulation and reliably absorb shocks. This makes them highly versatile. Our engineers produce solutions that are used in a wealth of industries, such as automotive, construction, and HVAC, not to mention in leisure products and design material. We also offer – in the form of DRAINplus – a drainage and infiltration system that, as an all-in-one solution, covers myriad applications, whether drainage, rainwater infiltration, or water treatment.

We also supply our customers with a wide selection of sustainable raw materials for their molded parts and technical applications: our recycled materials rEPS and Styropor® Ccycled™ protect your products sustainably.

Conventional materials such as the expanded foams polystyrene (EPS), known as styrofoam, hybrid materials (PS/polyolefin), Neopor®, and polypropylene (EPP) also boast unique properties that make them ideal for certain applications. EPS, for instance, is ultra lightweight, is 98 percent air, and reliably protects against damage. Thanks to its graphite component, Neopor®, on the other hand, insulates even better against heat and cold than EPS, whereas EPP is exceptionally resilient, making the molded part exceptionally durable. Hybrid materials marry the strengths of EPS and EPP in a single material and are used wherever these properties need to be combined.

We can work with you to develop the optimal solution for you – tailored to your specific needs.

rEPS

- Recycled expanded polystyrene comprises at least 95% recycled EPS/PS waste

- This waste consists of both PIR (post-industrial recyclate) and PCR (post-consumer recyclate)

- rEPS has the same properties as conventional EPS

- New packaging can be manufactured 100% from the material rEPS

Styropor® Ccycled™

- The material is made from plastic waste at consumer level (e.g. household waste) and from contaminated or mixed plastics

- Styropor® Ccycled™ comes with the same packaging and insulation properties as conventional EPS

- For prototypes from a vast array of industries, such as food packaging and thermoboxes

- ecoloop certification confirms that we are contributing to the circular economy with Styropor® Ccycled™

Josef Osterloh

Auf der Lage 3

49377 Vechta

T +49 4447 8008 570