EPP CAN WITHSTAND HEAVY STRAIN.

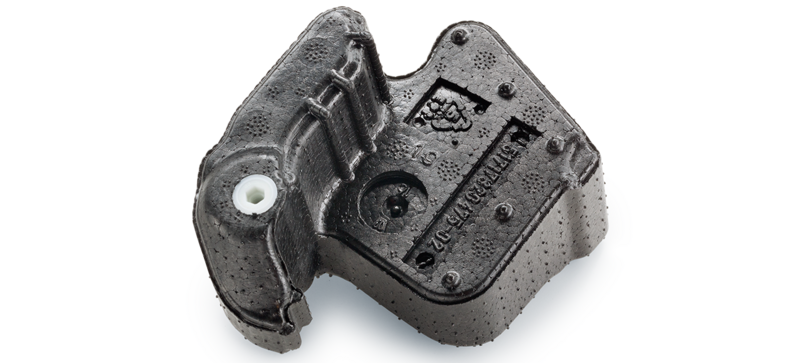

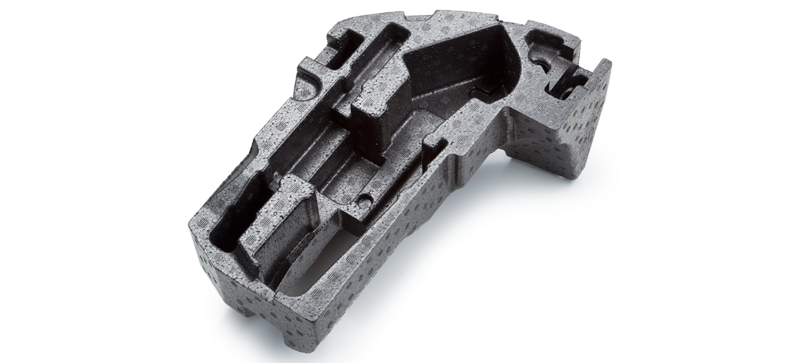

Technical molded parts made of expanded polypropylene (EPP) are indispensable in a number of industries – in car manufacturing, for example. Thanks to their outstanding energy-absorbing properties, EPP parts improve passive safety and provide better protection for vehicle occupants. Accordingly, they are used to make fenders, headrests, and other impact absorbers. EPP can absorb even more energy when used in combination with metal. One secondary benefit is the low weight of the innovative material: EPP molded parts thus cut fuel consumption and make cars more eco-friendly.

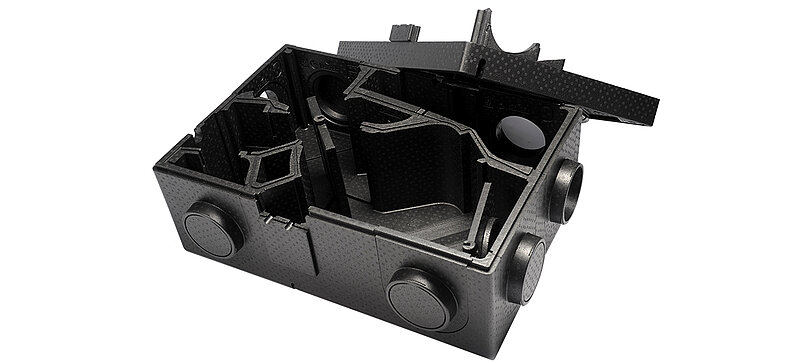

Due to the fact that it can be precisely shaped, EPP also cuts a good figure elsewhere – as a sun visor, paneling, or a toolbox for precisely accommodating breakdown sets. Its extraordinary insulating ability is also the reason why notable manufacturers in the heating and air conditioning industry use EPP molded parts from Storopack for their products.

Storopack Hans Reichenecker GmbH

Untere Rietstrasse 30

72555 Metzingen

T +49 (0)7123 164-0