RECYCLING MEANS USING RAW MATERIALS AS EFFICIENTLY AND SUSTAINABLY AS POSSIBLE.

Storopack is using more and more recycled raw materials in its packaging materials. And it’s no different with loose fill. EPS packaging chips consist of around 90 percent recycled materials. Storopack recycles the raw material from its own production and that of its customers.

The material is broken down and melted and then processed into frozen beads. These frozen beads are then expanded again to create loose fill packaging chips that boast the same outstanding packaging characteristics as products that do not contain any recycled materials.

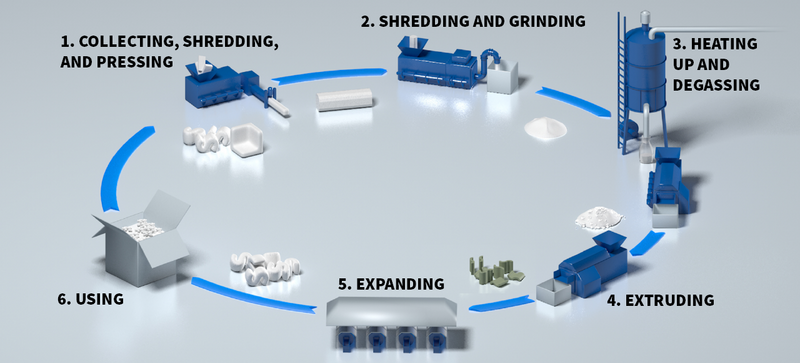

1. COLLECTING, SHREDDING, AND PRESSING

Used packaging made from EPS and loose fill packaging chips are shredded in compacting units and pressed into blocks.

2. SHREDDING AND GRINDING

Before the material can be further processed, the blocks are shredded and the EPS ground.

3. HEATING UP AND DEGASSING

The ground EPS is then heated up on a recycling extruder and degassed in the process. This step produces recycled PS granules.

4. EXTRUDING

The granules are melted on another extruder and a CFC-free blowing agent is injected. The resulting strands are cooled in water to prevent them from expanding. A granulator cuts them into small parts (“frozen beads”). These are the raw material for the production of loose fill made from EPS.

5. EXPANDING

The frozen beads are expanded to create loose fill packaging chips and then delivered to customers.

6. USING

The recycled loose fill packaging chips can be used as usual as the important material characteristics remain intact during the recycling process.

Storopack Hans Reichenecker GmbH

Untere Rietstrasse 30

72555 Metzingen

T +49 (0)7123 164-0