IT’S SAFE TO SAY THAT OUR EXPERTISE OFFERS PROTECTION.

Modern cars consist of many individual parts, including metal and electronic components, as well as parts made from expanded plastics, which we manufacture using a process certified in accordance with ISO and TS standards. Storopack foams are used in vehicle interiors, bumpers, headrests, and impact absorbers, effectively protecting passengers from injury, as they’re able to absorb the energy resulting from a crash. Our plastics are exceptionally lightweight and very malleable, increasing comfort in seat inserts and reducing energy consumption.

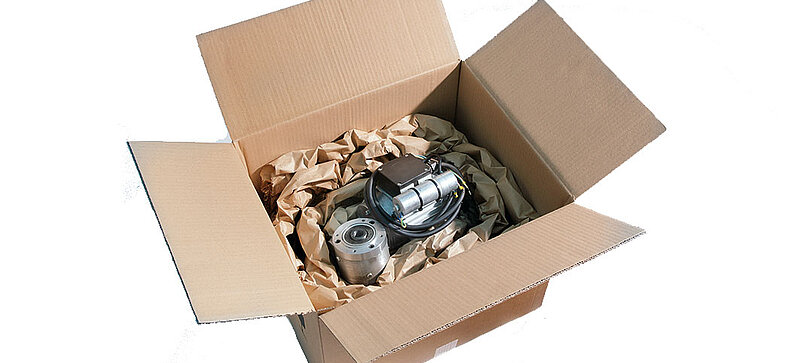

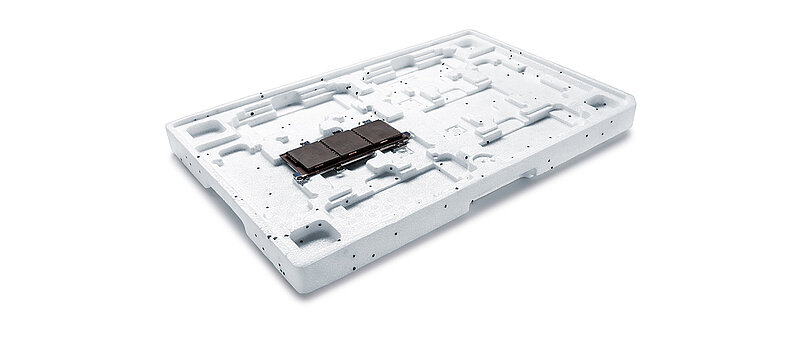

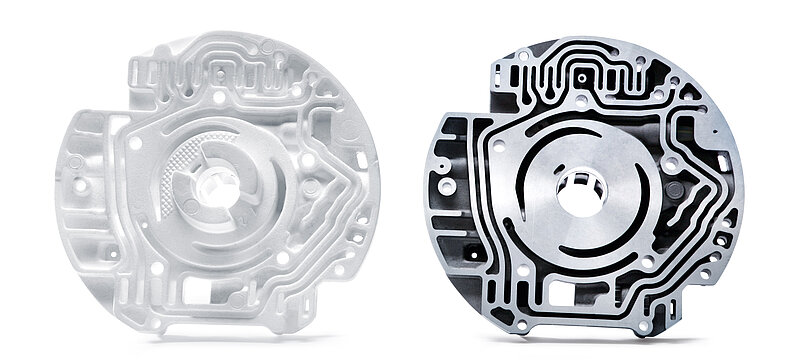

Storopack offers customized, reusable cargo carriers for existing and new model series that can be transported back and forth between production and destination. And we also have just the right solution for the manufacture of complex castings: with our foam models made from a special type of EPS, we also produce complex components for use in the innovative lost-foam casting process. High-quality components such as engines, transmissions, and spare parts are safely packed with our PAPERplus® paper cushioning systems and FOAMplus® foam packaging systems for worldwide shipping.