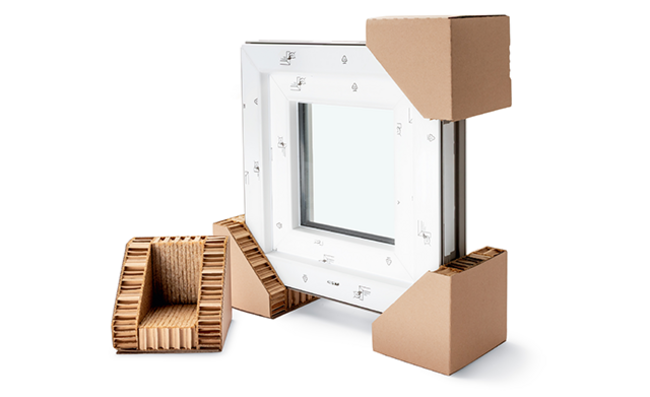

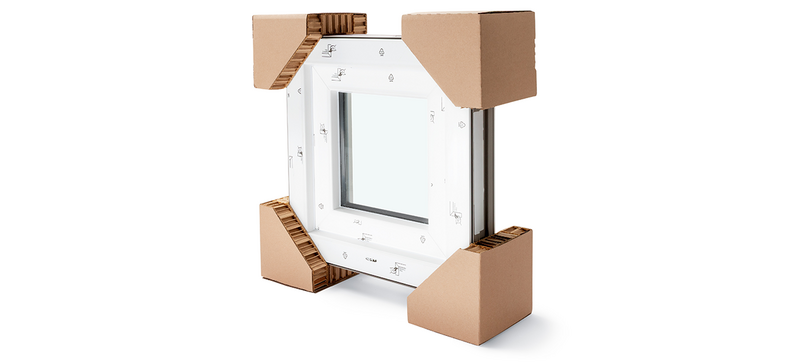

RENATURE® Honeycomb MEANS TAILORED PROTECTIVE PACKAGING MADE OF HIGH-PERFORMANCE SHOCK ABSORPTION PADS AND CARDBOARD.

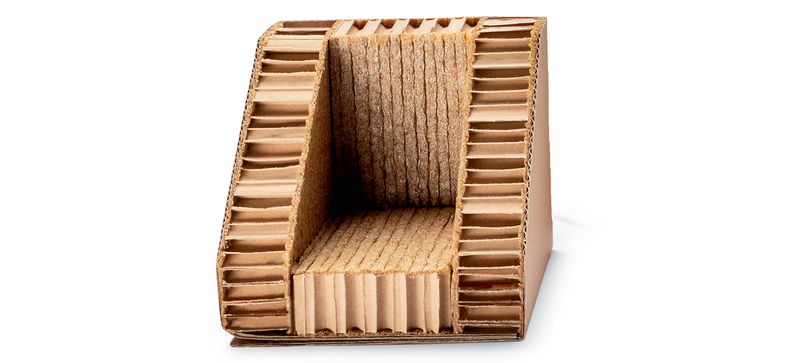

RENATURE® Honeycomb is the unique combination of high-performance pads and cardboard. The big advantage is that this customized protective packaging is completely recyclable with paper. This, and the fact that the patented solution offers similar exceptional packaging properties, makes it an attractive, sustainable, and flexible alternative to conventional EPS molded parts or protective packaging made from cardboard or corrugated board only. RENATURE® Honeycomb pads consist of a honeycomb paper network sandwiched between two starch-based foam liners. These combined pads are put together to form 3D shapes and thus tailored to the customer’s shipping goods.

The advantage of RENATURE® Honeycomb’s innovative combination is that the packaging solution places the pads in exactly the right position for optimal shock absorption. Compared to solutions made from conventional honeycomb cardboard pads, RENATURE® Honeycomb does not require any hot glue or plastic adhesive tape—instead, water is sufficient for bonding.

BENEFITS AT A GLANCE

Completely recyclable with paper

certified by the CEPI method

low environmental impact

reduced process costs

3D shape tailor-made to your product

suitable for mass production and small lots

packaged products are perfectly stackable

WHY RENATURE® Honeycomb IS YOUR BEST CHOICE FOR FUTURE-PROOF PACKAGING

COMPLIANT

It is designed with future packaging regulations in mind.

It is already compliant with EU Circular Economy Strategy and PPWR.

It helps to reduce single-use plastics.

It is recyclable and uses recycled material.

CIRCULAR

The foam pads are made almost exclusively from left-over yellow pea starch that would otherwise just be disposed of.

The honeycomb network is made from recycled paper.

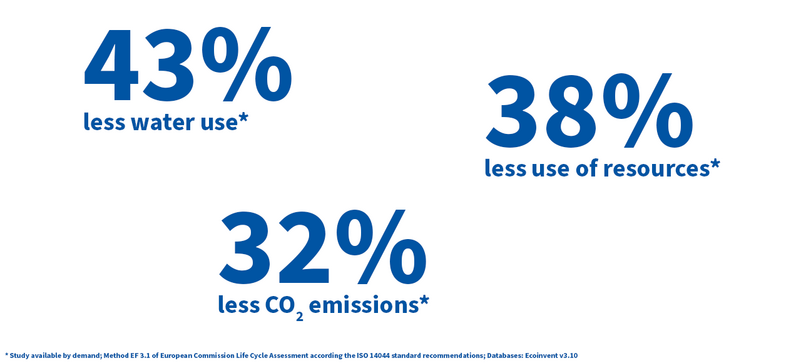

43% less water use*

38% less use of resources*

32% less CO2 emissions*

* Study available by demand; Method EF 3.1 of European Commission

Life Cycle Assessment according the ISO 14044 standard recommendations; Databases: Ecoinvent v3.10

CUSTOMER-DRIVEN

It answers end consumer demands.

It is customized protection.

It is easy to dispose of and recycle.

RENATURE® Honeycomb VS. CONVENTIONAL HONEYCOMB CARDBOARD PADS

| RENATURE® Honeycomb | CONVENTIONAL HONEYCOMB CARDBOARD PADS |

| Lower environmental impact as the foam liners are starch-based and the shock absorbers are only placed in areas where needed | Higher environmental impact as more material is required to get a similar packaging performance |

| Better shock absorption capacity due to the starch-based foam liners | The stiff paper liner needs to be pre-deformed to get a similar shock absorption performance |

| Starch-based foam liner has high shear resistance and eliminates abrasion risk by protecting the product’s surface | Paper liner increases the risk of abrasion due to fiber scratch effect |

| Lighter weight compared to standard honeycomb cardboard due to only using material where needed | Heavier weight compared to RENATURE® Honeycomb solution |

| Design efficiency reduces complexity as well as process costs for users at the customer’s packaging line due to only one component and thus less preparation time | Complex design and higher process costs for users at the customer’s packaging line |

| No adhesives, bonding without glue | Hot-melt adhesive |

| Disposable in the cardboard bin and recyclable | Disposable in the cardboard bin and recyclable |

YOUR CONTACT

Josef Osterloh

Auf der Lage 3

49377 Vechta

T +49 4447 8008 570