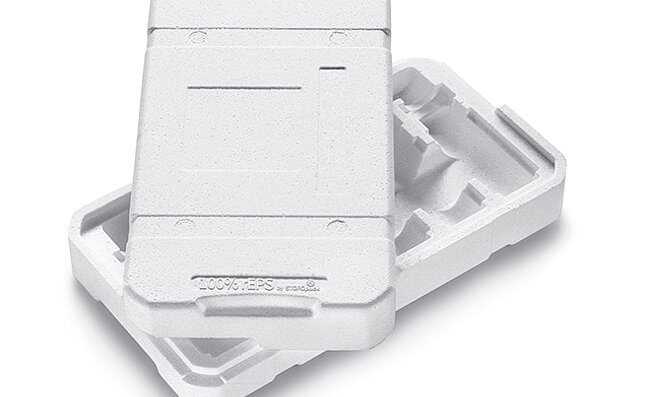

SUCCESSFUL DELIVERY OF FIRST PROTECTIVE PACKAGING MADE FROM 100 PERCENT POST CONSUMER RECYCLED MATERIAL

Metzingen, December 2020. The new raw material rEPS (recycled expanded polystyrene) is being well received in the industrial sector. Storopack already delivered the first protective packaging made from 100 percent rEPS to its customer. The material is made entirely from post-consumer EPS waste. The first customer of protective packaging made from 100 percent rEPS is Prevor. The French company in the medical sector is therefore choosing an exceptionally sustainable product to protect its shipping goods, because the excellent properties of Storopacks rEPS make it possible to use them without secondary packaging (such as cardboard or adhesive).

A first project with a leading manufacturer of cleaning equipment has also started in Germany and production of the protective packaging will start shortly.

Partnerships that Close the Loop

Protective packaging specialist Storopack is the first manufacturer with a fully integrated rEPS production process. Both the recycling and the production of rEPS beads take place exclusively at the company’s own locations. Storopack is currently working with two partners in order to put the “circular economy” principle into practice in terms of its protective packaging. Customers of a household appliances and consumer electronics retailer are able to return used EPS protective packaging once they have received their goods. This packaging will be forwarded to the company Eco2PR for further processing; finally, Storopack recycles the raw material in a patented process and uses it to produce new protective packaging.

This makes Storopack the exclusive packaging partner of the French network Réseau National des Recycleurs de Polystyrène expansé (R.N.R.P.), which has set itself the goal of creating an efficient recycling loop for expanded polystyrene (EPS) and a sustainable utilization of this raw material.

The innovative raw material rEPS plays a key role in ensuring that packaging is used in a more eco-friendly way. It combines sustainability with the positive material properties of EPS: good shock absorption, light in weight, excellent insulation and superb moldability. Protective packaging made from 100 percent rEPS not only offers an improved carbon footprint, but also the same reliable protection as products in conventional EPS.

Finding More Sustainable Approaches

Storopack is committed to promoting circular economies around the world in order to significantly increase the recycling rate. Among other things, the protective packaging specialist signed up to the Recyqualipso corporate initiative in France, which aims to find a way of recycling polystyrene yogurt pots into rEPS. Recyqualipso was launched in 2019 in France by Valorplast and Syndifrais, and with the financial and technical support of CITEO. In 2019, Storopack made more than 30 percent of its in-house products using renewable or recycled materials – and is striving to increase this figure to more than 50 percent by 2025.

Storopack Hans Reichenecker GmbH

Untere Rietstrasse 30

72555 Metzingen

T +49 (0)7123 164-0